Ⅰ. Distribution type

1. Low-voltage power distribution

The voltage level of low-voltage power distribution is usually in the low voltage range of 220V, 110V, etc., which is suitable for homes, office buildings, commercial buildings and some light industrial equipment.

The low-voltage power distribution system includes the following main components:

Substation: Located in a city or region, it converts medium-voltage electrical energy (such as 10 kV) into low-voltage electrical energy. The main distribution station includes transformers, circuit breakers, protection devices, etc.

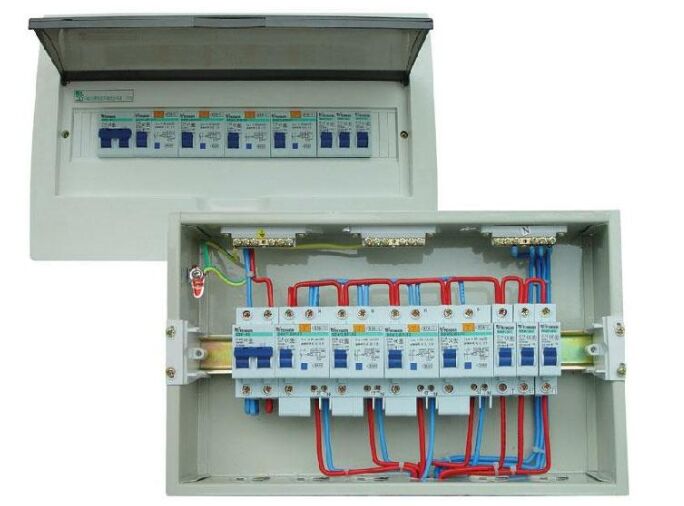

Distribution Panels: The distribution panel is an important part of the distribution panel, which includes circuit breakers, fuses, circuit protectors, etc., to control and protect branch circuits.

Distribution Boards: Installed in different areas of the building to further distribute low-voltage power from the main distribution station to different rooms, floors and electrical equipment.

Low-voltage power distribution has the following characteristics:

Safety: Low voltage makes system operation safer, reducing the risk of electric shock and fire.

Cost-effective: Low-voltage equipment is generally cost-effective and suitable for most domestic and commercial purposes.

Flexibility: Branch circuits can be designed and configured according to the needs of different purposes.

Ease of management: The distribution of switchboards and switchboards makes the management and maintenance of the system more convenient.

2. Medium voltage power distribution

The voltage of medium-voltage power distribution is usually between 1 kV and 35 kV, which may vary according to different standards and regions. This voltage level is suitable for industries, commercial buildings and public facilities, etc.

The medium voltage power distribution system consists of the following main components:

Substation: Located in a city or region, it converts high-voltage electric energy (such as 110 kV, 35 kV, etc.) into medium-voltage electric energy. Substations include transformers, switchgear, relays, etc.

Protection device: The medium voltage power distribution system is equipped with a variety of protection devices, such as relays and circuit breakers, to cut off the current in the event of current overload, short circuit, etc., to protect the safety of equipment and personnel.

Switchgear: In substations and main distribution stations, switchgear is used to control the flow and distribution of electrical energy. These devices can be controlled manually or automatically.

Medium-voltage cables: Medium-voltage cables are used to transmit electrical energy from substations or main distribution stations to different areas and further distribute it to different uses.

Medium voltage power distribution has the following characteristics:

Adaptability: It is suitable for large-scale industrial and commercial purposes, as well as some power consumption scenarios that require longer transmission distances.

Complexity: Design and O&M of medium voltage distribution systems can be more complex due to the higher voltage levels and larger equipment involved.

Reliability: Equipped with multiple protection and control devices to ensure the reliability and safety of power transmission.

Energy Efficiency: Higher voltage levels can reduce energy losses in wires and cables during power transmission.

3. High voltage power distribution

High voltage distribution is the process of transferring electricity from substations to main distribution stations, where it is stepped down and distributed to high voltage levels suitable for industrial, commercial and other large facilities. The voltage of high voltage distribution is usually between 35 kV and 500 kV, which can vary according to different standards and regions.

The high voltage power distribution system includes the following main components:

Substation: Located in a city or region, it converts ultra-high voltage power (such as 110 kV, 220 kV, etc.) into high voltage power. Substations include transformers, circuit breakers, relays, etc.

Switchgear: In substations and main distribution stations, switchgear is used to control the flow and distribution of electrical energy. These devices can be automated to enable remote operation.

Main distribution substation: Located in a city or large facility, the main distribution substation steps down high-voltage electrical energy to a voltage level suitable for industrial and commercial use, and then distributes it to various areas.

High-voltage cables: High-voltage cables are used to transmit electrical energy from substations to main distribution stations, and from the main distribution stations to different areas and facilities.

High voltage power distribution has the following characteristics:

Energy Efficiency: During power transmission, high voltage levels can reduce energy losses in wires and cables.

Large-scale power consumption: suitable for large-scale facilities to meet large-scale power consumption needs.

Stability: High-voltage systems usually have higher stability and reliability, and are suitable for scenarios with higher requirements on power supply.

4. Emergency power distribution

Emergency power distribution refers to the process of providing temporary power supply to critical facilities and equipment in the event of a power failure, blackout, or other emergency. This type of power distribution system is designed to ensure that critical facilities and equipment can continue to operate in the event of an emergency, thereby ensuring safety and protecting people and equipment.

Emergency power distribution is used in the following scenarios:

Medical facilities: Medical institutions such as hospitals and clinics require continuous power supply to ensure the normal operation of medical equipment, operating rooms and lighting.

Infrastructure: Urban infrastructure, such as water supply, gas supply, communication, etc., needs power support in emergency situations.

Emergency equipment: Firefighting equipment, emergency lighting, alarm systems, etc. require continuous power supply in emergency situations.

Traffic system: In emergency situations, traffic lights, emergency communication equipment, etc. need continuous power supply to maintain traffic safety.

Data Center: Data centers require a stable power supply to ensure the normal operation of servers and network equipment.

The emergency power distribution system consists of the following main components:

Monitoring and Control Systems: Modern emergency distribution systems may include monitoring and control systems that allow remote monitoring of the status of the power supply and operations.

Backup Generator: One of the common emergency power distribution solutions is a backup generator. These generators can work independently to generate electricity from fuel oil or other sources of energy.

Battery packs: For shorter outages, battery packs can provide temporary power to keep critical equipment running.

Automatic transfer device: In the event of main power failure, an automatic transfer device can connect a backup generator to critical equipment and circuits to ensure continuous power supply.

The emergency power distribution system has the following characteristics:

Automation: The automatic switching device and monitoring system make the switching and operation of the system more convenient.

Quick Response: The system must be able to respond quickly to a power outage or emergency, switching to backup power to keep equipment running.

Reliability: Emergency power distribution systems must be highly reliable to ensure a stable power supply at critical times.

Continuous Power: Emergency power distribution systems are designed to provide a continuous supply of power to keep critical facilities operating.

5. DC power distribution

DC power distribution is a method of transferring DC power from power plants or renewable energy installations to various areas. Compared with traditional alternating current (AC) power distribution systems, DC power distribution systems have advantages in some applications, especially in renewable energy integration, data centers, and some specific industrial scenarios.

The DC power distribution system includes the following main components:

DC-AC Converter (Inverter): Where AC power is required, a DC-AC converter converts DC power into AC power.

DC power plants/renewable energy installations: DC power can be generated from DC power plants or renewable energy facilities such as solar photovoltaic and wind power installations.

DC distribution system: DC power is transmitted to different areas through the distribution system, including distribution boards, switchboards and other equipment.

DC Converter: DC power needs to be converted into an applicable voltage level through a converter, and then transmitted to different areas.

DC cables: used to transmit electrical energy from power plants or renewable energy facilities to different areas.

The DC power distribution system has the following advantages:

Data Center: Computers and servers in data centers usually require DC power, and DC power distribution can reduce the loss of energy conversion.

Energy Efficiency: DC power is lost less during power transmission, thus making it more energy efficient in some cases.

Renewable energy integration: DC power is suitable for solar photovoltaic, wind energy and other renewable energy installations, which can be more easily integrated.

Electric energy storage: DC electric energy is more easily combined with electric energy storage technology to realize energy storage and release.

6. Medical power distribution

Medical power distribution is a power distribution system specially designed for medical facilities, aiming to ensure continuous and stable power supply for medical equipment and facilities, so as to ensure the health of patients and the normal operation of medical services. Medical facilities have special needs for power supply, because the medical environment involves people's health and life. Power outages can lead to medical equipment failure, interruption of procedures, and safety risks.

The medical power distribution system consists of the following main components:

Distribution panels and switchboards: transmit power from backup power sources to various areas, operating rooms, wards, etc., ensuring coverage of power supply.

Backup Power: In response to power outages, medical facilities are often equipped with backup power equipment such as backup generators, UPS (Uninterruptible Power System), etc.

Battery Pack: For short power interruptions, the battery pack can provide temporary power to ensure the normal operation of critical equipment.

Monitoring and Control Systems: Modern medical power distribution systems often include monitoring and control systems that allow remote monitoring of power supply status and enable remote operations and alarms.

Automatic switching device: When the main power supply is interrupted, the automatic switching device can connect the backup power supply to medical equipment and critical circuits, ensuring the continuity of power supply.

The medical power distribution system has the following characteristics:

Continuous power supply: Medical facilities require a continuous and stable power supply to ensure the normal operation of medical equipment and services.

High reliability: The system must be extremely reliable, ensuring a stable power supply under all conditions.

Power quality: The quality and stability of power supply is critical to the operation of medical equipment, and parameters such as voltage and frequency need to be considered.

Quick Response: Automatic transfer devices must be able to respond quickly to power outages to ensure backup power is available in a timely manner.

7. Industrial power distribution

Industrial power distribution is a power distribution system specially designed for industrial facilities, aiming to provide stable and reliable power supply for industrial production processes. The industrial environment usually has a large demand for power, and the production process has high requirements for the reliability and stability of power. Industrial power distribution systems need to meet the special needs of industrial production, including high power demand, stability of important production processes and reliability of equipment.

Industrial power distribution systems include the following main components:

In industrial premises, there may be distribution transformers, switchgear, distribution panels, etc. that distribute electrical energy to different devices and areas.

Transmits high voltage electrical energy from power plants to industrial facilities, where it is stepped down and distributed.

Inside industrial facilities, medium or high voltage power is further stepped down and distributed to different areas and production lines.

Industrial power distribution systems are equipped with various protection devices to ensure that the current is cut off in the event of current overload, short circuit, etc., to protect the safety of equipment and personnel.

Industrial power distribution system has the following characteristics:

Industrial production has high requirements on power quality, and it is necessary to ensure that parameters such as voltage and frequency are within an appropriate range.

Industrial production requires high reliability of power supply, so industrial power distribution systems must have high reliability to ensure uninterrupted production.

Industrial production may involve a variety of equipment and production lines, and industrial power distribution systems need to adapt to different demands and load changes.

Ⅱ. Problems in power distribution design

1. Existing problems

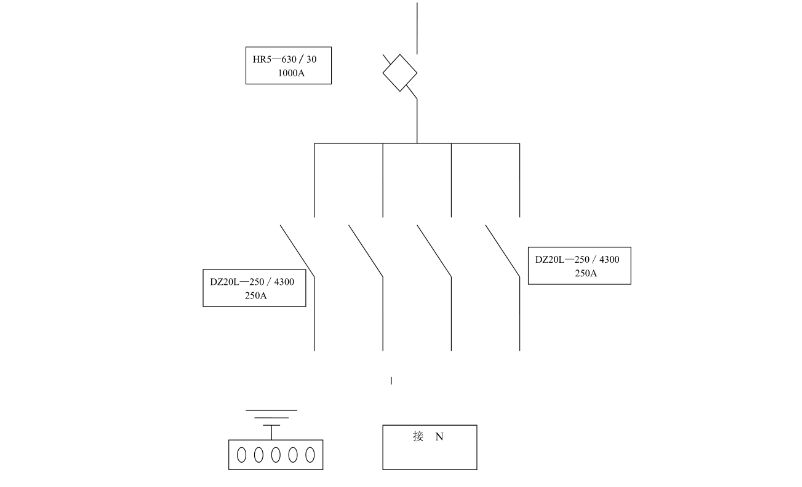

The selection of high-grade non-selective circuit breakers is a ubiquitous unreasonable design factor. When a large fault current occurs at the end, it may cause non-selective cut-off of one-stage or multi-stage circuit breakers. Excessive use of selective circuit breakers, even lines with only tens or hundreds of amperes, also use expensive selective circuit breakers.

breaker.

The selective circuit breaker is selected, but its parameter setting is incorrect, such as the rated current of the short-delay overcurrent release of the upper level is too small, even lower than the rated current of the instantaneous overcurrent release of the lower level circuit breaker, or the instantaneous overcurrent release of the upper level is too small. If the rated current of the buckle is too small, it may destroy the selective action.

2. Solutions

There is no selective requirement for the protective device of the terminal circuit, and non-selective circuit breakers or fuses can be used, but it should meet the requirements that the ground fault can be cut off within the specified time.

Selective circuit breakers should be selected at the head end of the feeder with relatively large current, and the setting requirements are as follows: the current of the instantaneous overcurrent release should be selected as large as possible; 1.2~1.3 times the current of the short-time delay or instantaneous overcurrent release, the delay time should not be less than 0.3~0.4s.

A new type of circuit breaker, with selective characteristics, is expected to meet the following requirements: the rated current of the circuit breaker frame can reach 63~400A, and the breaking capacity can reach about 15~30kA, which can meet most of the needs of general distribution lines; The instantaneous overcurrent release of the circuit breaker is modified to change the instantaneous release to have a delay characteristic of milliseconds.

Ⅲ. Power distribution engineering operation specification

As the name implies, the high and low voltage power

distribution project is the power distribution equipment connected to high voltage power distribution cabinets, low voltage switch cabinets and cables. Generally, power supply bureaus and substations use high-voltage distribution cabinets, which are then stepped down by transformers to low-voltage switchgears, and then to various power distribution panels. The control box and switch box are nothing more than power distribution equipment assembled with some switches, circuit breakers, fuses, buttons, indicator lights, meters, wires and other protective devices.

High and low voltage power distribution projects generally follow the operating specifications for carrying out their process cycles on all and part of the electrified disk:

1. The secondary windings with current transformers and voltage transformers should have permanent and reliable protective grounding.

2. The maintenance equipment should be separated from the operating equipment with obvious signs.

3. When working on the secondary circuit of the current transformer in operation, the following safety measures should be taken: prohibit any work on the circuit and wires between the current transformer and the short-circuit terminal; in order to reliably short-circuit the secondary coil of the current transformer , must use short-circuit sheet and short-circuit wire, prohibit the use of wire winding.

4. The staff who check the power-off protection and the secondary circuit are not allowed to perform any switching operations without the permission of the on-duty personnel.

5. When working on the secondary circuit of the voltage transformer in operation, the following safety measures should be taken: before the circuit is energized or withstand voltage test, the on-duty officer and relevant personnel should be notified, and personnel should be sent to guard the site, check the circuit, and confirm that no one is working The rear can be pressurized; when the secondary circuit is energized for the test, in order to prevent the reverse voltage from the secondary side to the primary, in addition to disconnecting the secondary circuit, the primary fuse should also be removed.

Ⅳ. The difference between high-voltage power distribution and low-voltage power distribution

1. High voltage power distribution:

High voltage electrical energy is typically transmitted at voltage levels of 110 kilovolts (kV) or above. Different regions and countries may have different high voltage standards. The loss of high voltage power transmission is relatively small, because the current is relatively small at high voltage, and according to the formula of power loss (P = I²R), the loss caused by resistance is low. High-voltage power works better when transmitted over long distances and is suitable for power transmission that connects different cities and regions.

2. Low-voltage power distribution:

Low-voltage power distribution is the process of transferring electrical energy at lower voltage levels from substations or high-voltage grids to end users such as homes, commercial buildings, and industrial facilities. Low voltage electrical energy is typically delivered at voltage levels of 220 volts (V) or less. Low voltage standards may vary in different countries and regions. Low voltage power transmission losses are higher because the current is higher at the lower voltage, resulting in increased resistive losses.

3. Difference:

Transmission distance: High-voltage power distribution is suitable for long-distance power transmission, while low-voltage power distribution is mainly used for distribution within cities or short distances.

Voltage levels: High voltage distribution uses higher voltage levels (typically above 110 kilovolts), while low voltage distribution uses lower voltage levels (typically below 220 volts).

Resistance loss: Since the resistance loss is proportional to the current, the current of the high-voltage power distribution system is small and the loss is low, while the current of the low-voltage power distribution system is large and the loss is high.

Ⅴ. How is the power distribution network structured and organized?

Basic build:

Power Plants and Substations: Electrical energy is initially generated in power plants and is usually delivered at high voltage (above 110 kV) to substations. Substations transform, distribute, and step down electrical energy in preparation for sending it further afield.

Power transmission system: The power transmission system transmits the electric energy generated by the substation to the main distribution stations in different regions through high-voltage transmission lines. These transmission lines are usually high-voltage cables or wires, capable of transmitting electrical energy over long distances.

High Voltage Distribution: High voltage distribution transfers electrical energy from the main distribution substation to distribution substations within urban and industrial areas. These substations step down the electrical energy and distribute it to smaller areas.

Main distribution station: The main distribution station receives high-voltage electrical energy from the transmission system, distributes it and steps it down in preparation for transmission to urban and industrial facilities.

Distribution Substation: A distribution substation receives electrical energy from high voltage distribution and steps it down to medium or low voltage in preparation for transmission to a smaller area.

Organization:

Distributed generation: With the development of renewable energy and distributed generation technology, some regions have begun to implement distributed generation, allowing small-scale power generation devices to inject power into the distribution network.

Radial Organization: This is a common organizational method in which high-voltage electrical energy is transmitted radially from the main substation, gradually stepped down and distributed to different areas and users. This approach is suitable for urban and industrial areas.

Ring organization: In some regions, distribution networks may be organized in rings, where power is transmitted within rings to provide backup paths in case of failures and interruptions.