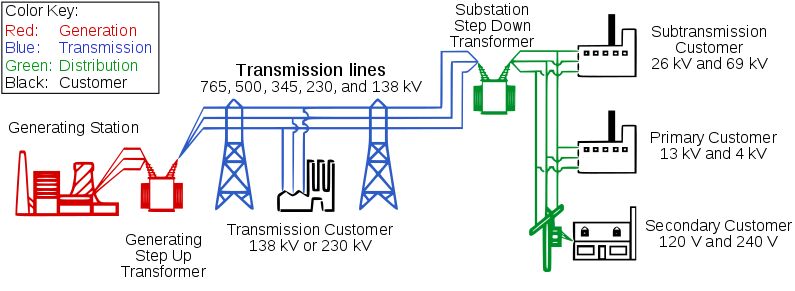

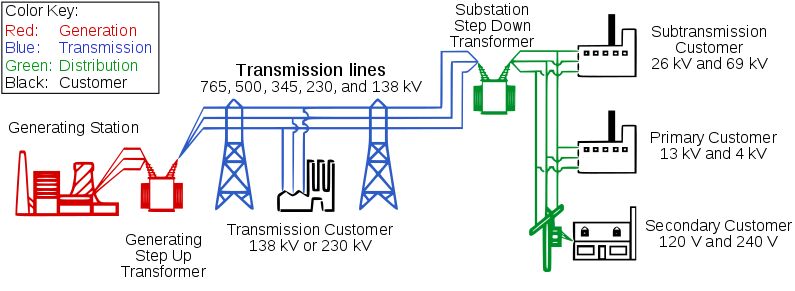

A power distribution system is an integral part of a power network whose main function is to distribute power from a power source (usually a power transmission system) to end users and various devices to meet different power demands. The power distribution system is responsible for converting the electrical energy transmitted by the high-voltage transmission line into a lower voltage and delivering it to various buildings, factories, homes and other places where electricity is used.

Power distribution is a link in the power system that is directly connected to users and distributes electric energy to users. The distribution system consists of distribution substations, high-voltage distribution lines, distribution transformers, low-voltage distribution lines and corresponding control and protection equipment.

The power distribution system refers to the system that transmits power from the transmission system to the user end; usually refers to the power line of 35kV or below, including related substations, transformers on utility poles or roadside transformer boxes, to the user end electric meter. Electric power distribution, or distribution, refers to the final stage of electricity delivery, moving electricity from the transmission system to individual consumers. Distribution substations are connected to the transmission system and use transformers to step down the transmission voltage to medium voltage between 2 kV and 35 kV.

Ⅰ. Power supply mode of power distribution

1. DC power supply mode

The DC power supply methods commonly used in power distribution systems are: two-wire system, used for power supply of urban trolleybuses, subway locomotives, mine traction locomotives, etc.; Electricity, electrolysis and electroplating.

The primary power distribution network is the network from the outgoing line of the distribution substation to the entrance of the distribution substation (or power distribution station). In China, it is also called high-voltage power distribution network. The voltage is usually 6-10 kV, and most cities use 10 kV power distribution. With the increase of urban load density, 20 kV power distribution scheme has been adopted. The main part of the primary distribution line drawn from the distribution substation is called the main line. The part branched off from the main line is called a branch line. Distribution transformers are connected to branch lines. There are two types of wiring in the primary distribution network: radial and ring.

The secondary power distribution network is a system composed of lines and components between the secondary lead-out line of the distribution transformer and the user's home line, also known as the low-voltage power distribution network. In addition to the radial and ring wiring methods, important users in the city can use double-circuit wiring. Urban areas with a high density of electricity loads use grid-style wiring. This kind of network is powered by multiple primary distribution main lines, and after stepping down through distribution transformers, it is connected to the secondary distribution network through low-voltage fuses. Since the adjacent primary distribution transformers in the secondary system are connected to different primary distribution trunk lines, it is possible to avoid power outages in the downtown area due to primary distribution line failures.

According to the structure of distribution lines, there are overhead lines and underground cables. Overhead lines can be used in rural areas and small and medium-sized cities, and underground cables should be used in large cities (especially downtown areas), tourist areas, and residential areas.

Ⅱ. End of power distribution system

1. Power distribution room

A distribution room is a dedicated space for housing electrical distribution equipment, control gear, and facilities related to power distribution. It is usually located inside buildings, factories, facilities or other places where electricity is used, and is the core component of the power distribution system. The main purpose of the distribution room is to convert, distribute and control electrical energy from the high voltage transmission system.

Some key features and components of a power distribution room:

Grounding system: The distribution room needs a good grounding system to ensure that the current can flow safely to the ground in the event of a fault, preventing electric shock and other hazards.

Transformers: Power distribution rooms often include transformers to convert high-voltage electrical energy from the transmission system to low-voltage electrical energy suitable for internal distribution.

Distribution equipment: The distribution room includes the main switchboard and the distribution switchboard for distributing electrical energy to different areas or floors. These devices ensure that electrical energy flows to different destinations as required.

Cables and wires: There will be a variety of cables and wires in the distribution room to carry the power from the transformers to the different distribution panels, switchgear, and other terminals.

Environmental control: Since there are many electrical equipment in the power distribution room, proper environmental control, such as ventilation, temperature control, etc., is usually required to ensure the normal operation and long life of the equipment.

Protection devices: The power distribution room may include relays, protection switches, and other devices to monitor parameters such as current, voltage, frequency, etc., so as to trigger protective operations in case of power abnormalities.

Circuit breakers and switches: The circuit breakers and switches in the power distribution room are used to control the connection and disconnection of the circuit, and to cut off the current in the event of a power failure to protect the safety of equipment and personnel.

Safety signs: There should be clear safety signs in the power distribution room, indicating the location of different equipment and facilities and safe operation procedures.

Remote monitoring: Modern power distribution rooms are increasingly equipped with smart technologies that allow for remote monitoring, fault diagnosis, and remote control to improve operational efficiency and responsiveness.

2. Distribution box

A distribution box is a device used to distribute and manage electrical energy and is commonly used in residences, commercial buildings, industrial facilities, and more. It is an important part of the power distribution system and is used to distribute electrical energy from the main power source to different circuits, equipment and power consumption areas.

Distribution boxes usually include main circuit breakers, branch circuit breakers, fuses, circuit protectors, grounding devices, and other electrical components. These components are used to control the flow of electrical current, interrupt it in the event of a fault, and provide additional protection.

The distribution box is used to distribute the electric energy from the main power supply or substation to different circuits to meet the power needs of different equipment and areas. It allows users to distribute power as needed, while providing circuit breakers and protective devices for safety.

The capacity of the distribution box depends on the needs, and the appropriate size of the box and electrical components can be selected to meet the electricity demand. Different applications may require distribution boxes with different current and voltage ratings.

Distribution boxes are usually designed as closed metal boxes to prevent personnel from touching dangerous electrical components. They are also equipped with appropriate protective devices such as earth leakage protectors to detect current leakage to reduce the risk of electric shock.

The branch circuits in the distribution box can be connected to different electrical equipment, such as lighting, sockets, electrical equipment, etc. Each branch circuit can be controlled and protected by circuit breakers or fuses.

The cables and conductors inside the distribution box direct the electrical energy from the main power source to the different branch circuits. Proper wiring ensures a steady flow of electricity to each consumer.

Modern distribution boxes are gradually introducing smart technologies, such as remote monitoring, timing control, energy management and other functions, to improve energy efficiency and operational convenience.

The distribution box needs regular maintenance, including checking the circuit breaker, the normal operation of the protective device, cleaning the inside, ensuring that the connection is tight, etc.

3. Switchboard

A switchboard is a device used to distribute electricity, manage circuits and protect electrical equipment. It is usually a closed metal box with various electrical components inside, which are used to distribute the electrical energy from the main power supply or substation to different circuits and electrical equipment.

The main components and features of the switchboard include:

Grounding: Grounding within a switchboard is used to connect metal parts of electrical circuits to ground for the safety of personnel and equipment.

Main Circuit Breaker: An electrical panel usually includes a main circuit breaker that shuts off power to the entire panel. This is a key device for maintenance and power cuts in emergencies.

Branch circuit breaker: There are multiple branch circuit breakers in the switchboard to distribute power to different circuits and consumers. Each branch circuit breaker can individually control the on-off of the corresponding circuit.

Power indicator light: Power strips are often equipped with a power indicator light to show if power is on.

Lighting and signage: There may be lighting inside the switchboard, as well as signage regarding electrical parameters, operating instructions, etc.

Fuses and Protectors: A switchboard may contain devices such as fuses, circuit protectors, etc. to cut off the current in the event of a current overload or short circuit to protect circuits and equipment.

Ⅲ. Main components of power distribution system

1. Substation: The substation is the starting point of the power distribution system and is used to convert the electrical energy transmitted by the high-voltage transmission line into a lower voltage suitable for distribution. Substations typically include transformers, switchgear and protective devices.

2. Cables and wires: Cables and wires are used to transmit power between various power distribution components. Their size and type are determined according to the requirements of current capacity and voltage level.

3. High-voltage power distribution: The high-voltage power distribution network is responsible for transmitting power from substations to main power distribution sites in different regions or regions. The voltage levels here are higher, typically in the range of 110 kV to 500 kV.

4. Power distribution network: The power distribution network transmits electricity from the main distribution station to various buildings, factories and homes. It usually involves medium and low voltage wires, with corresponding transformers and switchgear.

5. Main distribution station: The main distribution station is responsible for converting high-voltage power from the high-voltage distribution network into medium-voltage or low-voltage power suitable for cities or regions. Main distribution substations usually include transformers, switchgear and protective devices.

6. Distribution panels and switchboards: Distribution panels, or switchboards, are located in different areas within a building and are used to further distribute electricity to different rooms, floors and electrical appliances. They include circuit breakers, fuses, circuit protectors, etc. to control and protect circuits.

7. Circuit breakers and switches: Circuit breakers and switches are used to control the flow of electric current and to cut off the circuit in the event of a power failure to protect equipment and personnel.

8. Grounding system: The grounding system is used to connect the metal parts of electrical equipment and circuits to the ground to ensure the safety of personnel and equipment.

9. Protection and control devices: Protection and control devices in the power distribution system, such as relays, protection switches, etc., are used to monitor current, voltage and other parameters to trigger protection operations in case of power abnormalities.

Ⅳ. The role of power distribution system

1. Safety protection: The power distribution system protects the circuit through devices such as circuit breakers, fuses, and leakage protectors. When abnormal conditions such as current overload, short circuit, and leakage occur, these devices will cut off the circuit to prevent damage to electrical equipment and reduce the risk of fire and electric shock.

2. Power distribution: The power distribution system converts high-voltage power from substations into low-voltage power suitable for distribution, and transmits it to power-consuming areas such as buildings, factories and homes to meet the needs of different power-consuming equipment.

3. Power management: The power distribution system allows power to be distributed to different areas and devices as needed, thereby achieving effective power management and utilization. It enables users to control the distribution of power, ensuring that the power supply for each purpose is met.

4. Power quality: The power distribution system can improve power quality and reduce power fluctuations, harmonics and interference. This is especially important for some sensitive equipment and industries, such as computers, medical equipment, etc.

5. Power stability: The power distribution system ensures stable power supply for different power-consuming equipment and areas by controlling and distributing power. This helps avoid voltage fluctuations and frequency changes, maintaining stable operation of the power system.

6. Energy efficiency: Reasonable design and management of power distribution system can improve energy utilization efficiency and reduce energy waste and loss. An optimized power distribution strategy helps reduce energy costs.

7. Support new energy: The power distribution system can support the integration of new energy, such as solar and wind energy. Through intelligent control and management, renewable energy can be smoothly integrated into the power network to achieve sustainable energy supply.

8. Troubleshooting and maintenance: The structure of the power distribution system makes troubleshooting and maintenance easier. Different circuits and devices can be controlled independently so that in the event of a fault, only the affected area is affected and the entire power system is not affected.

Ⅴ. Power distribution system design

1. Design requirements

The design of the substation should be carried out according to the project development plan, correctly handle the relationship between short-term construction and long-term development, and properly consider the possibility of expansion. The design of the substation must proceed from the overall situation, and determine the design plan based on the comprehensive consideration of the load nature, power consumption capacity, engineering characteristics, regional power supply conditions, and environmental protection and energy saving requirements.

From the planning to the completion of the power distribution room, the general steps are as follows: determine the size and structure; determine the location; determine the detailed structure; inspect and approve the architectural drawings; construction; complete the building acceptance; Fire alarm, etc.; final acceptance.

To determine the size and structure of the power distribution room, first determine the function of the power distribution room (for substation, switch station, control, and multi-function), and then determine the location. From an economical point of view, the installation site is expected to be in the load center. Generally, after the main equipment is determined, the remaining building space is fully utilized, so that a rough architectural design drawing can be obtained, but a detailed structural drawing is required for construction. The construction can be started after the architectural drawing is completed, and the large power distribution room should be checked frequently.

The type of substation should be determined according to the condition of the electric load and the surrounding environment. For buildings with large loads, it is advisable to set up substations or semi-open-air substations; however, buildings with scattered loads should be equipped with combined substations; and in high-rise or large civil buildings, indoor substations or combined substations should be installed. Complete sets of substations; independent substations should be installed in residential areas of large and medium-sized cities with small and scattered loads; pole-mounted or high-bench type substations should be installed in residential areas of small and medium-sized cities and towns where the environment allows, when the transformer capacity is 315kVA or below .

For equipment selection, priority is given to the use of energy-saving complete sets of equipment and finalized products, which is the fundamental measure to implement the country's energy conservation and design quality assurance. Because the production plant can guarantee the quality of the complete set of equipment through the factory's advanced equipment and skilled workers' technical processing and assembly, as well as good testing conditions, it is generally economical and reasonable to choose complete sets of equipment and finalized products.

2. Location selection

The power supply distance is short and the power supply is easy. When the existing buildings or buried objects cause obstacles to the construction, the power supply route should be considered comprehensively, and the location of the power distribution room should be determined through research.

It should be close to the load center, the shorter the power distribution distance, the smaller the power loss and voltage drop, and the more economical the construction cost.

The surrounding environment is good. It should not be installed in places with a lot of dust, high temperature and humidity, next to machines with large vibrations, serious salt damage around equipment, or places that may be flooded by tides. However, when unavoidable, appropriate measures should be taken. In addition, it cannot be installed in places where flammable and corrosive gases may occur and remain. The power distribution room should not be located in places of type 0, 1, or 2, otherwise the electrical products should be of explosion-proof structure, or carry out explosion-proof construction. The height of the power distribution room set up in such places should be above 600mm from the ground to the first floor.

It should be avoided as much as possible to set up in places with poor foundations. If it cannot be avoided, it is necessary to improve the foundation or pile construction. In addition, the location of the power distribution room should have no impact on its adjacent ground and no impact on future development.

Ⅵ. The difference between power supply and power distribution

1. Power supply

Power supply refers to the process of converting different types of energy, such as fossil fuels, nuclear energy, renewable energy, etc., into electrical energy through various power generation equipment. The main purpose is to generate electricity to meet the electricity needs of the entire social and economic system. The supply of electricity is usually carried out in electric power plants, power stations or other energy conversion facilities. These facilities can be thermal power plants, nuclear power plants, solar farms, wind farms, etc., depending on the energy type and power generation technology. The electrical energy generated by the power supply usually has a relatively high voltage, usually high voltage or even extra high voltage.

This is to realize the long-distance transmission of electric energy. The high-voltage electric energy generated by the power supply is transmitted to substations in cities and regions through the power transmission system. The power transmission system includes high-voltage transmission lines, transformers and corresponding control equipment.

2. Power distribution

Power distribution is the process of converting high-voltage electrical energy from substations or main power sources into low-voltage electrical energy suitable for use in buildings, factories and homes. The main purpose is to distribute electrical energy from high-voltage transmission lines to various areas, buildings, and electrical equipment to meet the electrical needs of specific areas and equipment. Electricity distribution takes place in substations, distribution panels and switchboards within cities, regions and buildings. These facilities step down high-voltage electrical energy and distribute it to various circuits. Power distribution systems step down high-voltage electrical energy to low-voltage electrical energy suitable for domestic and industrial equipment, usually 110V, 220V, or other common low-voltage voltages.

Ⅶ. Advantages of Power Distribution System

1. The power distribution system can distribute the high-voltage electric energy from the substation to different areas, buildings and electrical equipment to meet different power demand.

2. Optimized power distribution system design and management can improve energy utilization efficiency, reduce energy waste and loss, and thereby reduce energy costs.

3. The power distribution system helps to improve power quality and reduce voltage fluctuations, harmonics and interference, thereby improving power stability and reliability.

4. Improve the safety and reliability of the power supply system. Power supply reliability includes real-time understanding of the power supply system, quick response to faults, and ability to restore power supply in a very short time for unexpected power failures. The main technical measures include: ring network power supply, cable-based and non-stop power operation; use of small current grounding, automatic compensation of grounding current, improve arc extinguishing rate; power distribution automation, fast self-healing and seamless self-healing; application of distributed power micro-grid , to maintain power supply for important users in the event of a large power grid outage.

5. Guarantee the quality of power supply. Circuits that are sensitive to harmonics are equipped with power quality analysis instruments for real-time monitoring. Once the harmonics exceed a reasonable range, the system can notify the operating personnel. The main technical measures include: voltage and reactive power optimization control; power distribution automation; application of flexible power distribution equipment.