Ⅰ. Describe power distribution from different angles

1. Technical perspective

Power distribution is the process of distributing electricity from the transmission system to consumer terminals, and it involves converting high-voltage electrical energy into low-voltage electrical energy suitable for different purposes.

The substation is a key link in the power distribution system, which is used to transform the high-voltage power of the transmission line into low-voltage power suitable for the distribution network. Substations typically include transformers, switchgear, protection devices and control systems.

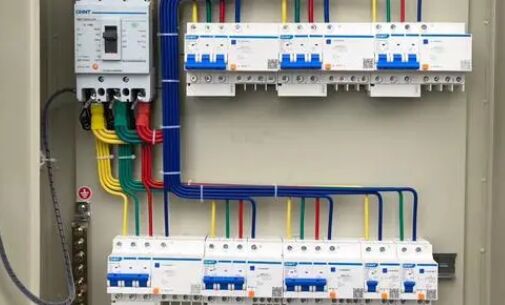

A switchboard is a device used to manage and distribute electrical power, directing electrical energy to different circuits and user equipment. Switchboards can be installed in different locations such as residences, offices, and factories according to requirements.

Cables and wires are the key media for the transmission of electrical energy in power distribution systems. They need to be selected according to the current, voltage and environmental needs to ensure the efficiency and safety of power transmission.

The substation is a key link in the power distribution system, which is used to transform the high-voltage power of the transmission line into low-voltage power suitable for the distribution network. Substations typically include transformers, switchgear, protection devices and control systems.

Switching devices control the flow of electrical energy and break circuits, while protective devices monitor current, voltage and temperature to trigger protective measures in the event of faults or overloads to protect systems and equipment.

In some cases, microgrids and distributed energy systems are used for more flexible and sustainable power distribution. These systems can integrate renewable energy and storage devices into distribution networks for autonomous energy production and distribution.

2. Engineering angle

From an engineering point of view, power distribution refers to the process of converting high-voltage electric energy transmitted by transmission lines into low-voltage electric energy suitable for user terminals in the power system. This involves designing, planning, installing, testing and maintaining various equipment and components to ensure the efficient, safe and reliable transmission of electrical energy.

Planning and Design Phase:

Determine power demand: Determine the required power load, voltage level and capacity according to the needs and uses of users.

Define cable routing paths: Plan the routing paths of cables, including medium and low voltage cables, ensuring the shortest distance and least resistance.

Selection of Transformers and Equipment: Depending on power requirements and cable routing, select appropriate transformers, switchboards, switchgear and protective devices.

Equipment and material preparation:

Procurement of equipment and materials: According to the design plan, purchase the required equipment and materials such as transformers, switchgear, cables, wires, and switchboards.

Check quality and specifications: Ensure purchased equipment and materials meet quality standards and specifications to ensure system reliability and safety.

Installation and connection:

Install the transformer: Install the transformer at a proper location, and connect the high voltage and low voltage side cables according to the design.

Arrangement of cables: Arrange medium-voltage and low-voltage cables according to the design plan, and follow safety and regulatory requirements.

Connecting switchgear: Installing and connecting switchgear, protective devices and control systems to ensure the system can be controlled and monitored remotely.

Test and debug:

Resistance test: Perform resistance test on cables and wires to ensure that the resistance value meets the standard and reduce energy loss.

Protection test: Test the function of the protection device in order to trigger the protection measures in the event of faults such as overload and short circuit.

Overall System Testing: Testing of the entire electrical distribution system to verify its operation under various load conditions.

Maintenance and Operations:

Regular Inspections: Regularly check the condition of equipment and cables, look for potential problems, and perform maintenance and repairs.

Troubleshooting: When a fault occurs, analyze and troubleshoot, and quickly fix the problem to reduce power outage time.

Data recording: record the operating data of the power distribution system, including current, voltage, load and other parameters, for performance analysis and optimization.

3. Economic perspective

Described from an economic point of view, power distribution refers to the process of converting high-voltage delivered electrical energy into low-voltage electrical energy suitable for user terminals in the power system.

Cost-benefit analysis:

Equipment cost: The procurement cost of transformers, cables, switchgear, protection devices and other equipment is the main component of the power distribution system. When selecting equipment, a cost-benefit analysis is required to balance price and performance.

ROI:

Investment analysis: For large-scale power distribution projects, return on investment (ROI) analysis is required to evaluate the relationship between the investment cost of the project and the expected benefits.

Long-term benefits: Some investments, such as the adoption of smart systems and renewable energy sources, may lead to more significant energy savings and cost benefits in the long run.

Energy Loss and Efficiency:

Resistive Loss: The resistance of cables and wires causes energy loss. Choose proper cable size and material to reduce resistive losses and reduce energy costs.

Increased Efficiency: By using high-efficiency transformers, optimizing cable routing and reducing cable lengths, the efficiency of the system can be increased and energy wasted reduced.

Electricity price and electric load:

Impact on electricity prices: Fluctuations in electricity prices will affect electricity costs. When designing a power distribution system, electricity price trends need to be considered in order to optimize load distribution and time of use.

Electricity load: Reasonable distribution of electricity loads and avoiding overloading during peak hours can reduce excess electricity charges and energy waste.

Operation and maintenance cost:

Maintenance and overhaul: Regular maintenance and overhaul of equipment can prolong the life of the equipment and reduce the risk of sudden failure, thereby reducing maintenance costs.

Failure costs: Sudden failures may lead to power outages and production interruptions, resulting in direct and indirect economic losses. Failure costs can be reduced by implementing suitable protection and preventative measures.

Electricity price and electric load:

Impact on electricity prices: Fluctuations in electricity prices will affect electricity costs. When designing a power distribution system, electricity price trends need to be considered in order to optimize load distribution and time of use.

Electricity load: Reasonable distribution of electricity loads and avoiding overloading during peak hours can reduce excess electricity charges and energy waste.

Sustainability and Environmental Protection:

Green Technology: Adoption of green technology and renewable energy, while the initial investment may be high, can reduce energy costs in the long run while providing environmental advantages.

Environmental protection requirements: Some regions may have environmental regulations and standards, which have an impact on the design and operation of the power distribution system, and compliance costs need to be considered.

4. Reliability perspective

Describing power distribution from a reliability perspective refers to ensuring that electrical energy is reliably transmitted in the power distribution system to meet the needs of user terminals while minimizing the risk of failures and outages.

Equipment reliability:

Equipment Selection: Choose high-quality, reliable equipment such as transformers, switchgear, and protection devices to reduce the risk of failure.

Equipment life: consider the design life and reliability of equipment, and avoid using aging equipment or equipment that may have hidden dangers.

Maintenance and Prevention:

Regular maintenance: Regularly inspect and maintain equipment to identify and deal with potential problems in time to avoid equipment degradation or failure.

Preventive measures: Reduce the risk of failure and damage by regular cleaning, tightening bolts, checking insulation and tightening connections.

Fault detection and protection:

Protection devices: Configure appropriate protection devices in the power distribution system, such as overload protection, short circuit protection and ground fault protection, as well as fast power-off function to reduce fault propagation.

Fault Detection: Use fault indicators, sensors, and monitoring systems to monitor the status of cables and equipment in real time to detect faults early.

Quick response:

Remote monitoring: Configure the remote monitoring system, which can monitor the system status in real time, find and respond to problems in time.

Fault recovery: When a fault occurs, the fault point can be quickly located and measures can be taken quickly to minimize the power outage time.

5. Environmental perspective

Describing power distribution from an environmental perspective refers to considering the minimization of negative impacts on the environment when designing, constructing and operating power distribution systems to promote sustainable development and environmental protection.

Renewable Energy:

Solar and wind energy: Integrate renewable energy sources into the electricity distribution system, such as photovoltaic panels and wind turbines, to reduce dependence on traditional energy sources.

Distributed energy: The use of distributed energy systems, such as solar microgrids, can provide independent power supply and reduce transmission losses.

Energy Efficiency and Conservation:

High-efficiency equipment: choose high-efficiency, low-energy-consumption equipment, such as high-efficiency transformers, energy-saving cables, etc., to reduce energy loss.

Load management: optimize power load, avoid energy waste during high load periods, and improve energy efficiency through load balancing.

Environmentally friendly materials:

Cables and equipment: Select environmentally friendly materials to manufacture cables and equipment to reduce environmental pollution and resource consumption.

Low volatile substances: reduce the use of volatile organic compounds and reduce the risk of air pollution.

Carbon Footprint Reduction:

Greenhouse Gas Emissions: Reduce greenhouse gas emissions and lower your carbon footprint through the use of clean energy, energy efficiency improvements, and carbon capture technologies.

Viable alternatives: Look for alternatives with lower carbon emissions, such as using electricity instead of oil-powered equipment.

Sewage and Waste Management:

Sewage treatment: rationally handle and treat the generated sewage to prevent water source and soil pollution.

Waste Management: Properly dispose of waste equipment and materials to ensure compliance with environmental regulations.

Environmental Impact Assessment:

Life cycle assessment: conduct a full life cycle assessment of the power distribution system, including the stages of manufacture, transportation, use and end-of-life, to assess its environmental impact.

Ecologically fragile areas: In ecologically fragile areas, special attention should be paid to environmental protection to reduce disturbance to local ecosystems.

6. From the perspective of new energy

Describing power distribution from the perspective of new energy means that in the power system, the electric energy generated by renewable energy (such as solar energy, wind energy, hydropower, etc.) is integrated into the power distribution system to realize the distribution, transmission and utilization of green energy.

Photovoltaic power generation system:

Solar Panels: Solar panels that convert solar energy into electricity are installed on buildings, solar farms, etc. to generate DC power.

Inverter: An inverter converts DC power into AC power for transmission and use in the power distribution system.

Environment and Sustainability:

Reduce emissions: The application of new energy helps to reduce greenhouse gas emissions and air pollution, and has a smaller impact on the environment.

Resource Sustainability: Renewable energy sources do not depend on finite fossil fuel resources, helping to ensure the long-term sustainability of energy supply.

Energy storage:

Battery systems: Store excess renewable energy for release during periods of peak energy demand.

Energy storage technology: In addition to batteries, there are other energy storage technologies, such as compressed air energy storage, gravity energy storage, etc.

7. Safety angle

Equipment and material selection:

Quality certification: Select equipment and materials that are qualified and certified to ensure they meet safety standards.

Insulation performance: Ensure that cables, wires and insulating materials have sufficient insulation performance to prevent electric shock and leakage.

Protective devices and switchgear:

Overload and short circuit protection: Configure overload and short circuit protection devices to prevent equipment overload and short circuit from causing danger.

Differential protection: Differential protection devices are used to monitor current differences and detect electrical faults in time.

Arc and Short Circuit Protection:

Arc flash lamps: Arc flash lamps are used in electrical equipment to promptly alert personnel of electrical faults and the presence of arcs.

Arc protection device: Use arc protection device to reduce the danger of arc and protect personnel safety.

Equipment installation and maintenance:

Qualified installation: The installation of equipment and cables should comply with standards and specifications to avoid potential safety hazards caused by incorrect installation.

Periodic Inspection: Regularly check the condition of the equipment to ensure that there is no damage, wear or rust, and to detect problems early.

Ⅱ. Protection and safety measures in power distribution system

1. Common protective measures

Differential protection: Differential protection can monitor current differences, detect electrical faults in time, and reduce the possibility of equipment damage and personal injury.

Overload protection: The overload protection device will automatically cut off the circuit when the current exceeds the rated value of the equipment, preventing overloading of wires and equipment, avoiding fire and equipment damage.

Ground fault protection: The ground fault protection device can detect whether the current flows back to the ground, prevent electrical equipment leakage, and reduce the risk of electric shock.

Short-circuit protection: The short-circuit protection device can quickly cut off the circuit to prevent short-circuiting of current and avoid equipment damage, fire or electric shock risk.

Insulation monitoring: The insulation monitoring system can detect the insulation status of cables and equipment to avoid electrical faults and electric shocks caused by insulation damage.

Arc fault protection: The arc fault protection device can detect the arc, find and cut off the arc early, and prevent the arc from causing a fire.

Emergency power-off button: An emergency power-off button is set in the power distribution system to facilitate personnel to quickly cut off the power supply in an emergency to ensure personnel safety.

Safety signs and warnings: Set safety signs and warning signs on equipment and cables to remind personnel of potential dangers and safety precautions.

2. Importance of protection and safety measures

Environmental Protection: Preventing accidents can reduce environmental pollution and damage and protect the environment.

Personnel safety: Protection measures can prevent electric shock, fire, electric arc and other accidents to ensure the safety of personnel in the working environment.

Equipment protection: Protection measures can prevent equipment from being damaged, burned or degraded, and prolong the life of equipment.

Reduced risk of blackouts: Appropriate protection measures can reduce the risk of blackouts caused by faults and accidents and ensure a stable power supply.

Ⅲ. Distribution loss

1. Distribution loss refers to the energy loss that occurs during the transmission of electric energy from the power station to the user terminal in the power system. These losses can occur in various links such as cables, transformers, switchgear, wires, etc., including resistance loss, hysteresis loss, transformer iron loss, etc.

2. Methods to reduce power distribution loss:

Choose high-efficiency equipment: Choose high-efficiency transformers, switchgear, and cables that reduce losses during energy conversion and transmission.

Distributed energy and energy storage: adopt distributed energy systems to bring energy generation closer to users and reduce transmission losses. At the same time, energy storage technology can store energy at low load and release it at high load, reducing energy loss.

Optimizing cable size and material: According to the load demand, choose the appropriate cable size to reduce the resistance loss. Using low-resistance cable materials also helps reduce losses.

Reduce current load: through load management, avoid overload operation, reduce current flow through cables and equipment, thereby reducing resistance loss.

Improve the power factor: improve the power factor of the system, avoid the waste of reactive power, and improve the efficiency of the system.

Energy management system: Equipped with an energy management system to monitor electricity consumption in real time, find abnormal electricity consumption or leakage, and reduce energy loss.

Maintenance and regular inspection: Regularly inspect and maintain cables, equipment, connectors, etc. to ensure their normal working condition and avoid energy loss due to damage or aging.

Ⅳ. Distribution network voltage level

The distribution network voltage level refers to the nominal voltage value series used in the distribution network. The voltage level of the distribution network not only determines the insulation level required by the power supply equipment, but also directly affects the power loss and voltage loss.

The voltage level of the distribution network is based on the national voltage standard, combined with the transmission voltage of the power system and the distribution conditions of the power supply area, the voltage of the distribution network at all levels selected. The voltage level of the distribution network not only determines the insulation level required by the power supply equipment, but also directly affects the power loss and voltage loss. For power users of different nature, different capacity, and different power supply distances, using different voltage levels to supply power can obtain the necessary power supply reliability and better economy, and is conducive to ensuring qualified power supply voltage quality. Therefore, the distribution network is usually constructed and operated with several standard voltage levels.

For large and extra-large industrial enterprises or civil buildings, three-level voltage is generally used, that is, the regional substation (total step-down substation) reduces the voltage of 110 kV (220 kV) or 35 kV to 10 kV, and local The (user) substation then drops to 0.38 kV/0.22 kV to supply power to electrical equipment. If there is a medium-voltage electrical equipment, the first stage is reduced to 3-6 kV to supply power to the medium-voltage electrical equipment, and then the 3-6 kV is reduced to 0.38 kV/0.22 kV to supply power to the low-voltage power distribution equipment.

1. Voltage level selection

Minimize the power loss of the distribution network to be economically reasonable; determine the appropriate voltage level from the perspective of development to adapt to the increasing trend of distribution network load density and prevent future waste in improving projects; The combination of transformation work should facilitate the development of the entire distribution network and ensure the flexible, safe and reliable operation of the distribution network; the coordination and feasibility of equipment supply and manufacturing technology.

Due to various reasons in the development of power supply, some countries or regions have formed too many non-standard power supply voltage levels, resulting in: complex voltage management, affecting the quality of power supply; too many types and specifications of equipment, it is difficult to achieve product standardization and normalization , It hinders the development of equipment manufacturing technology and affects the improvement of product quality and economic benefits.

2. Development of distribution network voltage levels

In the process of implementing power supply voltage standardization, in order to further reduce power loss, promote the standardization and standardization of power equipment, reduce the number of spare parts and facilitate operation and maintenance management, it is necessary to further simplify the voltage level and reduce the transformation level.

The development trend of the voltage level setting of the distribution network in various countries is: large cities use four-level voltage for power supply, and general cities use three-level voltage for power supply. For example, the voltage levels in London, England in the early 1970s were: 275/132/66/11/0.415 kV, 275/132/33/0.415 kV, 275/132/22/0.415 kV, 275/132/66/33/ Various combinations of 0.415 kV and 275/66/22/0.415 kV, etc., implement partition power supply, and the plan requires that 22 kV be gradually canceled and become 275/132 or 66 or 33/11/0.415 kV. France plans to cancel the voltage levels of 150, 90, 63, and 5 kV, and mainly adopt 380/225/20/0.38 kV. The Federal Republic of Germany mainly uses 380/110/20 or 10/0.4 kV. The original voltage level in Tokyo, Japan is 500/275/154/66/30(20)/6/0.2(0.1) kV, and it has been decided to change the voltage below 66 kV to 66/20/0.4 kV.