Ⅰ. PMIC - Energy Metering

Ⅱ. Physical Characteristics of PMIC - Energy Metering

Ⅲ. Electrical Characteristics of PMIC - Energy Metering

PMIC, which stands for Power Management Integrated Circuit, is a type of integrated circuit that specializes in managing and controlling power in electronic devices. Energy metering PMICs, also known as energy measurement ICs or energy monitoring ICs, are a specific category of PMICs designed to measure and monitor energy consumption in electronic systems.PMIC - Energy Metering

The primary function of energy metering PMICs is to accurately measure various electrical parameters such as voltage, current, power, and energy consumption. These ICs are commonly used in applications where energy monitoring and management are essential, such as smart meters, energy management systems, building automation, and renewable energy systems.

Key features and functions of PMICs used for energy metering include:

1.Energy Measurement: Energy metering PMICs provide precise measurement of energy consumption in real-time. They calculate and accumulate energy usage over a specific period, allowing for accurate monitoring and analysis of power consumption.

2.Voltage and Current Sensing: These PMICs incorporate voltage and current sensing circuits to measure the voltage and current values of the power being consumed. They utilize sensing techniques such as current transformers or shunt resistors for current measurement and voltage dividers for voltage measurement.

3.Power Calculation: Energy metering PMICs perform power calculations based on the measured voltage and current values. They calculate parameters such as active power, reactive power, and apparent power, providing comprehensive information about power consumption.

4.Energy Accumulation: These PMICs include registers or counters to accumulate the energy consumed over a specific period. They store the accumulated energy value, which can be read and reset as needed for monitoring and billing purposes.

5.Calibration and Accuracy: Energy metering PMICs often offer calibration options to ensure accurate energy measurement. Calibration can compensate for component tolerances and variations, ensuring high measurement accuracy.

6.Communication Interfaces: Some energy metering PMICs feature communication interfaces such as SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit). These interfaces facilitate data transfer and communication with external devices or systems, enabling integration with higher-level control systems and data retrieval for monitoring and analysis.

7.Protection Features: Energy metering PMICs may include protection features such as overvoltage protection (OVP) and overcurrent protection (OCP). These features safeguard the PMIC and the connected components from potential electrical faults or failures.

8.Power Supply Regulation: Energy metering PMICs often incorporate voltage regulators to provide stable and accurate power supply voltages for the internal circuitry, ensuring measurement accuracy and reliable operation.

Energy metering PMICs play a vital role in energy management, enabling accurate measurement, monitoring, and analysis of energy consumption. They provide the necessary functionality to measure voltage, current, power, and energy, allowing for effective energy management, billing, and optimization of power usage.

Physical Characteristics of PMIC - Energy Metering

The physical characteristics of PMICs used for energy metering can vary depending on the specific device, manufacturer, and application requirements. However, here are some common physical characteristics associated with energy metering PMICs:

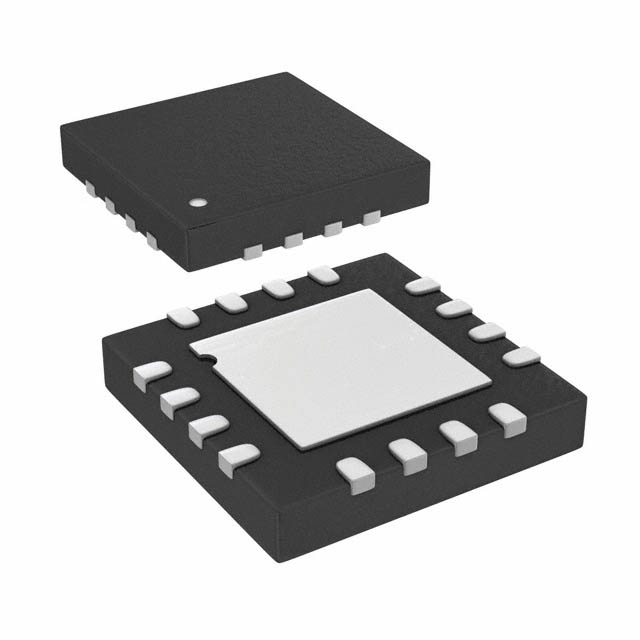

1.Package Type: Energy metering PMICs are typically available in various package types, such as QFN (Quad Flat No-Lead), TSSOP (Thin Shrink Small Outline Package), SOIC (Small Outline Integrated Circuit), or BGA (Ball Grid Array). The package type determines the physical size and form factor of the PMIC.

2.Pin Count: Energy metering PMICs can have a range of pin counts, depending on the complexity of the device and the number of input/output connections required for energy measurement and communication.

3.Thermal Dissipation: Energy metering PMICs may generate heat during operation due to power dissipation. To ensure proper thermal management, they may include features like thermal pads, exposed thermal vias, or other mechanisms for efficient heat dissipation.

4.Mounting Options: Energy metering PMICs can be mounted on printed circuit boards (PCBs) using surface mount technology (SMT) or through-hole technology (THT), depending on the design requirements and manufacturing processes.

5.Operating Voltage and Temperature Range: Energy metering PMICs have specified operating voltage ranges within which they can function reliably. They also have defined temperature ranges within which they can operate without thermal issues.

6.Communication Interfaces: Some energy metering PMICs feature communication interfaces, such as SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit), for data transfer and communication with external devices or systems.

7.Indicator LEDs: Some energy metering PMICs include indicator LEDs to provide visual feedback on the status of energy measurement, power supply, or fault conditions.

8.Protection Features: Energy metering PMICs may include protection features such as overvoltage protection (OVP) and overcurrent protection (OCP) to safeguard the PMIC and connected components from potential electrical faults or failures.

9.Power Supply Regulation: Energy metering PMICs often incorporate voltage regulators to provide stable and accurate power supply voltages for the internal circuitry.

It's important to note that the specific physical characteristics of energy metering PMICs may vary based on the manufacturer, product family, and application requirements.

Electrical Characteristics of PMIC - Energy Metering

The electrical characteristics of PMICs used for energy metering can vary depending on the specific device, manufacturer, and application requirements. Here are some common electrical characteristics associated with energy metering PMICs:

1.Input Voltage Range: Energy metering PMICs have a specified input voltage range within which they can operate. This range is typically determined based on the power supply voltage requirements of the system or application in which the PMIC is used.

2.Measurement Accuracy: Energy metering PMICs provide a specified measurement accuracy for parameters such as voltage, current, power, and energy. The accuracy is typically expressed as a percentage of the measured value or in terms of the number of bits of resolution.

3.Voltage Sensing Range: Energy metering PMICs can measure a specific voltage range. The voltage sensing range depends on the design and application requirements and can cover a wide range of voltage levels, from low voltages to high voltages.

4.Current Sensing Range: Energy metering PMICs have a specified current sensing range within which they can accurately measure the current flowing through a load. The current sensing range can vary depending on the design and application requirements, covering a wide range of current levels.

5.Power Measurement Range: Energy metering PMICs are designed to measure power accurately over a specific power range. This range can vary based on the device's design and application requirements, covering a wide range of power levels.

6.Communication Interfaces: Energy metering PMICs may include communication interfaces such as SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit). These interfaces allow for data transfer and communication with external devices or systems, enabling the retrieval and processing of energy measurement data.

7.Calibration and Linearity: Energy metering PMICs often provide calibration options or features to improve measurement accuracy. Calibration compensates for component tolerances and variations, ensuring better linearity and accuracy in energy measurement.

8.Power Supply Regulation: Energy metering PMICs incorporate voltage regulators to provide stable and accurate power supply voltages for the internal circuitry. These regulators ensure reliable operation and measurement accuracy.

9.Protection Features: Energy metering PMICs may include protection features such as overvoltage protection (OVP) and overcurrent protection (OCP) to safeguard the PMIC and connected components from potential electrical faults or failures.