Ⅰ. Introduction to circuit protection

Ⅱ. The main goal of circuit protection

Ⅲ. Common types of circuit protection

Ⅳ. Working principle of circuit protection

Ⅴ. Importance of circuit protection

Ⅰ. Introduction to circuit protection

The environment around electronic circuits is always changing. Many unpredictable factors such as human body static electricity, lightning surges, and misuse always threaten the normal operation of electronic equipment. Therefore, the function and significance of the protection circuit are very important. After years of development, the protection circuit has developed step by step from the simplest fuse to various complicated devices today, and they each take on different roles.

Circuit protection refers to the process of taking various measures in electrical systems or electronic equipment to ensure safe and stable circuit operation. In power systems, electronic equipment and communication systems, circuit protection is very important because it can prevent accidents caused by circuit overload, short circuit, overvoltage and other faults or abnormal conditions, protect the safety of equipment and personnel, and protect the system from damage.

Circuit protection is mainly to protect the components in electronic circuits from being damaged under overvoltage, overcurrent, surge, electromagnetic interference, etc. With the development of science and technology, electric/electronic products are becoming more and more diverse and complex. A power supply protection circuit is a circuit used to protect the power supply of electronic equipment from damage or failure, and is used to provide protection when the circuit power supply voltage is abnormal or the circuit fails.

Circuit protection is usually achieved by using devices such as protective devices, circuit breakers, fuses, relays, etc. These devices can detect according to parameters such as current, voltage and time, and quickly cut off the circuit when abnormal conditions are detected, so as to protect the safe operation of equipment and systems.

Protection device: used to monitor the voltage in the circuit, when the voltage exceeds or falls below the set value, the protection action is triggered.

Circuit breaker: A circuit breaker is an automatic switching device that quickly cuts off the current to protect equipment and circuits when there is an overload or short circuit in the circuit.

Fuse: A fuse is a current protection device that contains a length of molten conductor that melts and cuts off the circuit when the current exceeds its rated value.

Relay: A relay is an electromagnetic switching device that responds to changes in current or voltage through electromagnetic excitation for circuit protection and control.

Ⅱ. The main goal of circuit protection

1. Prevent arc and fire: By quickly cutting off the fault circuit, avoid the occurrence of arc and fire to protect the safety of equipment and buildings.

2. Prevent overload: prevent the current in the circuit from exceeding the rated capacity of the device or line. Overloading can cause wiring to overheat, equipment damage, and even fire.

3. Prevent undervoltage: protect the circuit from the influence of low voltage to avoid unstable operation or failure of equipment.

4. Prevent overvoltage: prevent the voltage in the circuit from exceeding the withstand capacity of the equipment or system. Overvoltage may cause equipment breakdown or damage to electronic components.

5. Prevent short circuit: detect and cut off the short circuit fault in the circuit in time, prevent excessive current from flowing through the circuit, so as to prevent damage to electrical equipment or fire.

6. Protect equipment and personnel safety: Ensure equipment and personnel are protected from electric shock and other hazards by quickly disconnecting power or isolating faults.

Ⅲ. Common types of circuit protection

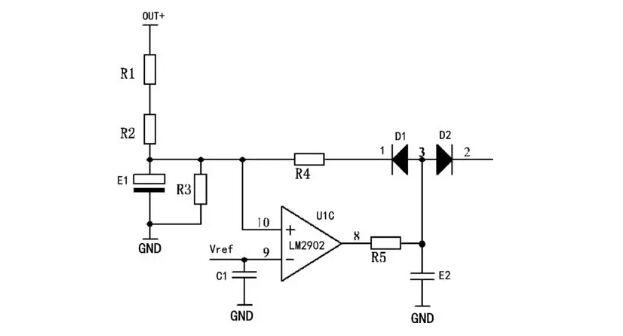

1. Overvoltage protection

Overvoltage protection refers to a protection circuit that automatically disconnects the power supply circuit when the power supply voltage exceeds the rated voltage. In electronic circuit design, a common protection method is to use Zener diodes for overvoltage protection. It is mainly used to prevent damage to electronic components caused by overvoltage or electrostatic discharge. It is widely used in various electronic system products such as telephones, fax machines, and high-speed transmission interfaces (USB, IEEE1394, HDMI, SATA), especially electronic communication equipment. How to avoid damage to electronic equipment due to abnormal voltage (or electrostatic discharge (ESD) is particularly important.

Overvoltage protection is used to protect circuits from excessive voltage, preventing equipment damage or failure. Overvoltage protection can be applied to different electrical and electronic equipment, such as power supplies, computers, home appliances, communication equipment, etc. The main goal of overvoltage protection is to ensure that the voltage is maintained within a set safe range to protect equipment and systems from overvoltage damage.

Common overvoltage protection methods:

Surge arresters: Surge arresters are mainly used to protect power supplies and power systems from lightning strikes and overvoltages. Surge arresters absorb excess voltage and direct it to ground.

Relay: Relay can be used to control switching power supply. When the voltage is abnormal, the relay can quickly cut off the power supply to protect equipment and circuits.

TVS diode: TVS (Transient Voltage Suppressor) diode is a special kind of diode. Its main function is to turn on quickly when the voltage exceeds a certain threshold, and drain the overvoltage current to the ground to protect the subsequent circuits or equipment from damage.

Voltage detector: The voltage detector is used to monitor the voltage and trigger the protection action when the voltage exceeds or falls below the set value. Once overvoltage is detected, voltage detectors can protect equipment by cutting power or triggering other protective measures.

Fuse: The fuse is a current protection device. When the current exceeds the rated value, the fuse in the fuse will blow, cut off the circuit, and play the role of overvoltage protection.

2. Short circuit protection

The main function of the short circuit protection circuit is to disconnect the closed circuit in time to ensure the safety of subsequent devices when a short circuit occurs in the circuit system. Short circuit protection is used to detect and cut off the short circuit fault in the circuit in time to prevent excessive current from flowing through the circuit and avoid equipment damage or fire. Circuit breakers, fuses, and differential protection devices are often used for short-circuit protection.

When a short circuit occurs in the power system, the current in the circuit will instantly increase to several times or even ten times the normal state. We can take advantage of this feature and put fuses in series in the circuit. When the current increases to the fusing current of the fuse, the fuse will blow due to its own overheating and open the circuit, which is one of the most common protection circuits.

The main goals of short circuit protection:

Prevent overcurrent: Short circuit faults will cause the current in the circuit to increase abnormally, which may far exceed the rated value of the device or line, resulting in overcurrent phenomenon. The primary goal of short-circuit protection is to quickly cut off the circuit and prevent excessive current from continuing to flow, so as to avoid equipment overload, damage or burnout.

Fire prevention: Excessive current generated by a short circuit fault can easily cause wires, cables or other electrical components to heat up, causing a fire. By cutting off the circuit in time, the short circuit protection can avoid the occurrence of fire or prevent the spread of fire.

Protecting equipment: Electrical equipment usually has its rated operating current and power range, and a short-circuit fault may cause the current to exceed the rated value, making the equipment unable to work normally or damaged. The goal of short-circuit protection is to ensure that the equipment operates within a safe range and prolong its service life.

Common short circuit protections are:

Differential protection: Differential protection is used to monitor the current difference in the circuit. If the current difference exceeds the set value, it indicates that there may be a short circuit fault, and the differential protection device will trigger the action and cut off the circuit.

Short-circuit protector: A short-circuit protector is a device specially used for short-circuit protection. It can quickly detect a short circuit in a circuit and cut off the current quickly to protect equipment and circuits.

3. Overcurrent protection

The power supply protection circuit can detect whether the power supply current exceeds the set value. If the power supply current exceeds the set value, the circuit will disconnect the power supply to prevent damage to the equipment caused by excessive power supply current.

Overcurrent protection is a measure used to protect a circuit or device from overcurrent. Overcurrent refers to the phenomenon that the current in the circuit exceeds the rated or design value. Overcurrent faults may be caused by short circuits, overloads, fault voltages, equipment failures, or other causes.

The main goal of overcurrent protection is to detect overcurrent in the circuit in time and take corresponding measures to prevent excessive current from flowing through the circuit and protect the safety of equipment and lines. Overcurrent protection can be applied to different types of circuits and equipment, such as power supplies, motors, transformers, generators, electronic equipment, etc.

Common overcurrent protection methods:

Current Relay: The current relay is used to monitor the current in the circuit and trigger the protection action when the current exceeds the set value. It can be used to find overload or other overcurrent faults.

Differential Protection: Differential protection is used to monitor current differences in circuits and can also be used to detect overcurrent faults.

Overcurrent protection device: An overcurrent protection device is a device specially designed for overcurrent protection and can be configured according to specific application requirements.

Rectifier overcurrent protection: In power electronics applications, such as converters, inverters, etc., there is usually rectifier overcurrent protection to prevent device damage.

4. Over temperature protection

Overtemperature protection is a measure used to protect electronic equipment, electrical equipment, or other systems from damage or malfunction when exposed to high temperatures. When the temperature of the equipment or system exceeds the set safety range, the over-temperature protection will be triggered, and corresponding measures will be taken to prevent the temperature from continuing to rise and protect the equipment from damage.

Over-temperature protection components are widely used in occasions that have special requirements on temperature. According to the operating principle, such protection components can be divided into chemical-actuated type and low-temperature alloy-actuated type. The main feature of chemical-actuated products is that they can be used as low-temperature products (some can reach 48°C), but the structure is more complicated and the cost is high. The low-temperature alloy type is mainly operated by a low-temperature fuse with a larger diameter. It must be ensured that the heat generated by the rated current will not melt the fuse.

The main goal of over-temperature protection is to ensure that the equipment operates within a safe temperature range, and avoid dangers such as device failure, burnout, melting or fire caused by excessive temperature.

Common over-temperature protection methods:

Temperature sensor: The temperature sensor is used to monitor the temperature of the equipment or system, and feed back the temperature information to the over-temperature protection circuit. Common temperature sensors include thermistors, thermocouples, and temperature sensor chips.

Temperature alarms: In some devices, over-temperature protection is not only about cutting off the power, but also alerting the user that the temperature of the device is too high by triggering an alarm or displaying a temperature warning.

Temperature controller: The temperature controller monitors the temperature of the equipment in real time according to the information provided by the temperature sensor, and controls the temperature of the equipment. When the temperature exceeds the set threshold, the temperature controller can trigger protection actions, such as reducing power, cutting off power supply or issuing an alarm.

5. Reverse polarity protection

Reverse polarity protection is a measure used to protect electronic equipment or circuits from misconnection or reverse power supply. The power supply protection circuit can detect whether the power supply is reversely connected. If the power supply is reversely connected, the circuit will disconnect the power supply to prevent the power supply from being reversely connected and causing damage to the equipment.

The main goal of reverse polarity protection is to detect the polarity of the power input, ensure it is connected correctly, and take appropriate action when a wrong connection is detected, preventing damage to the circuit or equipment.

Common reverse connection protection methods:

Controllable switch reverse polarity protection: Controllable switches (such as thyristors or field effect transistors) can be used to detect the polarity of the power input and quickly cut off the power when a wrong connection is detected to prevent reverse current from entering the device.

Voltage detector: The voltage detector can be used to detect the voltage polarity of the power input terminal, and trigger protective actions, such as cutting off the power or triggering an alarm, when a wrong connection is detected.

Relay protection: use a relay at the power input terminal for polarity detection, if a reverse connection is found, the relay will cut off the power to protect the equipment.

Grounding protection is a measure used to protect the safety of electrical equipment and personnel. The main purpose is to prevent or reduce the electric shock damage to the human body when the shell or conductor of the electrical equipment is in danger of electric shock.

A power protection circuit detects a fault in the grounding system, and if the grounding system fails, the circuit disconnects power, preventing damage to equipment from ground faults.

Ground protection can reduce the risk of insulation breakdown of electrical equipment and reduce equipment damage due to ground faults or leakage faults.

Common grounding protection methods:

Shell grounding: Reliably ground the shell of electrical equipment to prevent the shell from being charged and reduce the risk of electric shock.

Ground fault protector: The ground fault protector is used to detect whether there is a ground fault in the electrical equipment. Once the ground fault is detected, the protector will cut off the power supply and prevent the fault current from passing through the casing of the equipment.

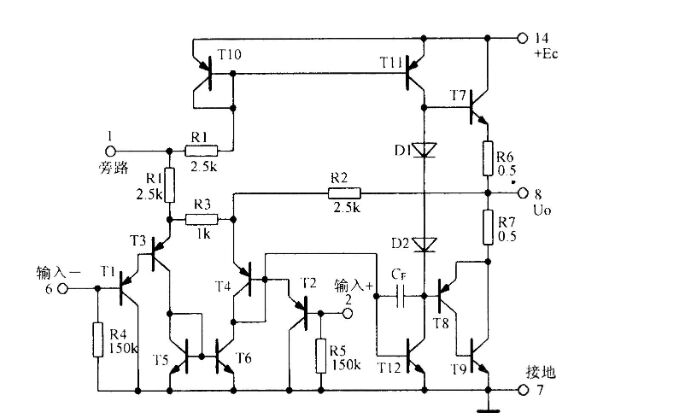

Ⅳ. Working principle of circuit protection

The working principle of the circuit protection circuit is to protect the power system from damage or failure by limiting the power supply voltage and current or preventing the power supply from being reversed, so as to ensure the safety and reliability of the power supply system. The key to the working principle of circuit protection is to monitor and detect faults in time, so that protective measures can be taken quickly to prevent faults from causing greater damage or danger.

When selecting a circuit protection circuit, factors such as the load, current, and power supply voltage of the circuit need to be considered, and an appropriate circuit protection circuit should be selected according to the specific situation. At the same time, the protection circuit needs regular inspection and maintenance to ensure the reliability and stability of the circuit.

Specific circuit protection steps:

Circuit protection first needs to monitor parameters in the circuit, such as current, voltage, temperature, etc. Different types of protective devices monitor different parameters according to their design goals.

Once abnormal conditions are detected in the circuit, the circuit protection device will immediately identify these abnormal conditions as faults.

After detecting a fault, the circuit protection device will trigger the corresponding protection action to prevent further expansion of the fault or avoid damage to equipment and personnel.

To protect equipment and circuits from damage or to avoid safety hazards, circuit protection devices interrupt electrical circuits. Breaking the circuit prevents fault current from flowing through the device, preventing it from being overloaded or damaged.

Ⅴ. Importance of circuit protection

1. With the development of electronic products, the function (integration) of IC is getting stronger and stronger, and its "worth" is naturally more and more expensive, so it needs to be protected.

2. The circuit protection device can monitor abnormal conditions in the circuit in time, such as overcurrent, overvoltage, overtemperature, short circuit and other faults, so as to quickly cut off the circuit when a fault occurs, and avoid damage or burnout of the equipment caused by fault current. They play a role in protecting equipment from overload, overvoltage, overcurrent and other factors, prolonging the life of equipment and reducing the cost of repairing and replacing equipment.

3. There are more and more mobile electronic products, such as handhelds, PDAs, notebook computers, camcorders, digital cameras, CD players, etc. These electronic products all need battery components as protective components in battery components and battery chargers.

4. Circuit protection detects and cuts off the overload or short circuit of the equipment in time to avoid energy waste and improve energy utilization efficiency.

5. Electronic products need to prevent lightning strikes and interference between power lines and telephone lines to ensure normal communication and personal safety of users. Therefore, with the development of electronic products, the demand for over-current and over-voltage protection components is on the rise.

Tags:circuit protection